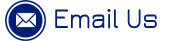

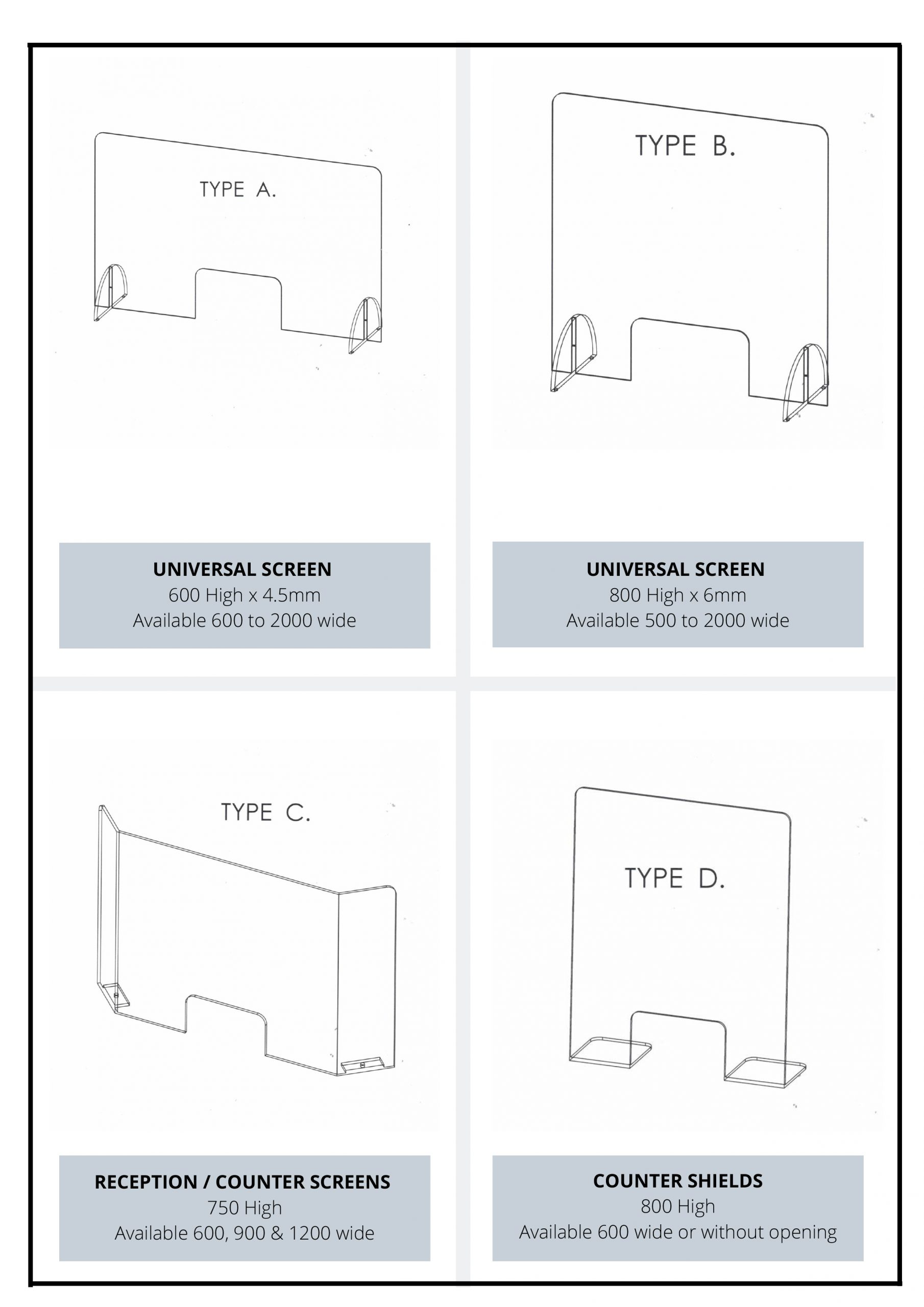

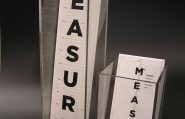

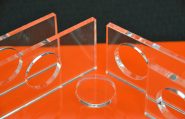

We currently manufacture a range of Sneeze Guards and Protection Screens

to suit many different applications.

Screens are available for :-

Fast Food Outlets

Reception Counters

Chemists & Pharmacies

Medical Professionals

Hospitals

Bakeries

Butchers

Supermarkets

Grocery Stores

Sales Counters

Delicatessens

Fish & Chip Shops

Service Stations

Hotel Lobbies

Liquor Outlets

Why Choose Us?

We have over 45 years of experience in designing and manufacturing safety screens

Choose from our 10 different proven designs that will suit most situations.

Buy your PERSPEX SCREENS direct from our Melbourne Factory and save $$$

We regularly make Screens to suit your special needs, particularly for Fast Food Outlets and Businesses with varying Counter heights.

Our factory is able to make most screens with a 48 hour turnaround. We understand the urgency of protection. Specialising in Melb Metro and all Victorian Country areas.

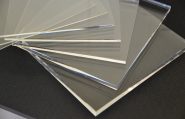

We supply only Quality Acrylic and Polycarbonate materials, including Perspex®, Plexiglass and Lexan®.

*COMMERCIAL *INDUSTRIAL *HOME & HOBBY

You’re Welcome to Visit

CUT-TO-SIZE ACRYLIC MELBOURNE is a Trademark and business operated by PLASTICS FOR INDUSTRY. We have a proven record of supplying top quality materials and great customer service.

By Phoning and buying direct, You save time and money.

Your questions are answered straight away.

Get a price quickly.

Our prices are much better than buying online.

We Cut-to-Size While-U-Wait.

Free and instant advice.

COMPARE THE 5 BEST REASONS TO USE PERSPEX® ACRYLIC or POLYCARBONATE

ADVANTAGES OF PERSPEX® ACRYLIC

- Up to 20 times greater impact strength than glass

- Will not shatter into small fragments like glass if broken

- Excellent Weather and Chemical resistance

- Lightweight, less than 1/2 that of glass, making it safe and easy to handle.

- Exceptional clarity ( better than glass ) with no optical distortion

DISADVANTAGES

- Relatively low impact resistance compared to Polycarbonate

- Not self extinguishing

- Notch sensitive. Avoid cutting sharp internal corners. Refer to our guide in DIY for cutting and drilling information

ADVANTAGES OF LEXAN® POLYCARBONATE

- Incredible Impact strength – 250 times greater than glass

- Easy to cut and drill without cracking

- Can be Cold bent to Angles and curves without heating

- Excellent fire rating properties – Self extinguishing

- Available with an Abrasion Resistant UV coating, making it the “Ultimate” clear plastic glazing material

DISADVANTAGES

- Relatively poor Chemical resistance compared to Acrylic

- Scratches easily ( unless coated with abrasion resistant surface )

- Not as rigid as Acrylic ( ie. more flexible )

DISADVANTAGES

- Relatively low impact resistance compared to Polycarbonate

- Not self extinguishing

- Notch sensitive. Avoid cutting sharp internal corners. Refer to our guide in DIY for cutting and drilling information

DISADVANTAGES

- Relatively poor Chemical resistance compared to Acrylic

- Scratches easily ( unless coated with abrasion resistant surface )

- Not as rigid as Acrylic ( ie. more flexible )

Please contact our Professional staff for more information, helping you make the right decision for your application.

Common uses for Acrylic and Polycarbonate include:

- Forklifts

- Earth moving equipment

- Security screens in Banks, Hospitals, Prisons, Police stations, Railway stations, Bus stop shelters.

- Skylights

- Windows

- Picture Frames

- Horse floats

- Boat Windows

- Aircraft Windows

- Helicopter Windows

- Race car Windows

- Pergolas

- Partitions

- Pool Fencing

- Display units

- Machine safety guards

- Balustrades

- Off-road vehicles

- Caravans